Sheet material wrapping system

Category:

Sheet material wrapping system

Auto horizontal stretch wrapper

Horizontal wrapper wraps tube or plate that won’t fit on a turntable, require banding, compression or extra packing for shipment. It has a proven record of success in many industries such as profiled product, tubular product and plank stuff etc.

We offer a wide variety of options to meet your specific requirements. Each application is evaluated to provide the right solution to your needs.

Specification

Rotating ring inner diameter: 450-2000mm (to be customized)

Wrapping dimension: Width & Height: to be designed; Length: 1800-5000mm; Weight: 300-1000kgs

Rotating ring speed: Max. 33rpm

Compressed air pressure: 0.5Mpa

Air consumption: 10L/M

Rotary ring

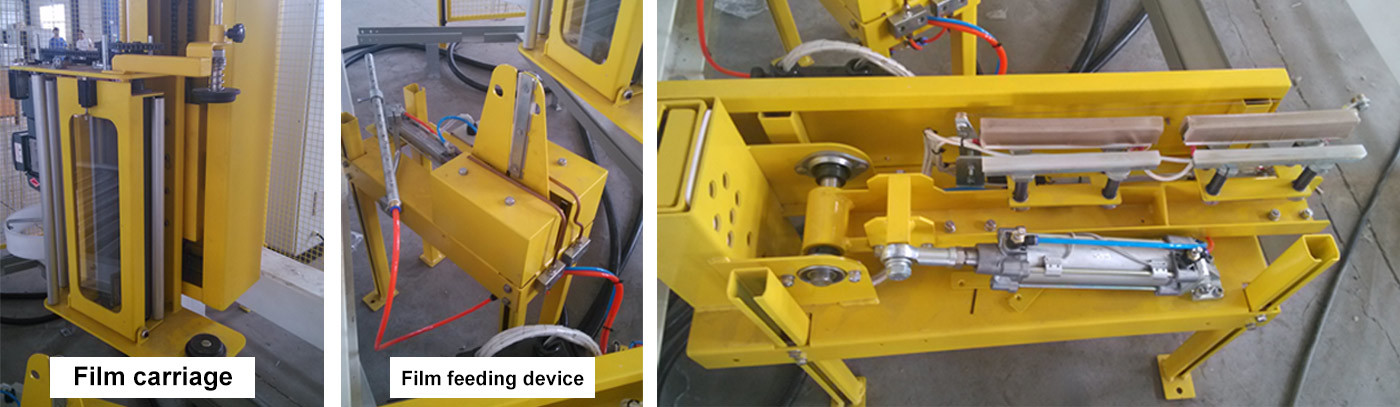

Film carriage

Pre-stretch film carriage

Width: 500mm;

Core size: 3’’;

Film roll diameter: max 240mm

Thickness: 17-35μm

Auto cutting & feeding film device (Pneumatic control)

Hold the film head for feeding;

Automatically cut the film after wrapping and hold film for the next pallet

Pneumatic components: AirTAC brand

Air consumption: 1000ml

Air pressure: 0.4-0.6Mpa

Top presser (Option)

Control system

Ring rotating speed controlled by the inverter

In-feed & out-feed conveyor speed controlled by the inverter

Start and finish cycles are controlled by photocells

Auto film cutting.

Auto rotary arm wrapper

Machine main frame

Gantry type frame, made of square steel tube, material: Q235 steel

Driving motor base is installed on the frame

The rotary arm are fixed on the frame connecting with slew bearing

Frame size: (to be confirmed by drawing)

Driving device for rotary arm

Frequency control motor with brake

Brand of motor: SEW

Power rated: 1.5KW

Rotary arm speed: n=15rpm (frequency motor with brake)

Two position limits equipped on two ends of rotary arm

Film carriage

Open-door type pre-stretch film carriage, stretch ratio 250% (1m to 3.5m), with spare sprocket ratio 200% for customer to replace for different stretching.

Film carriage lifting driving: chain driving, good stability and high reliability

Driving reducer: worm gear reducer

Motor power: 0.37kw, SEW brand

LLDPE pre-stretch film

Stretch wrapping film: Core size: 3''

Film width: 500mm

Diameter: max 260mm

Thickness: 12-35μm

One roll of stretch film to be supplied along with machine for trial running

Film carriage delivery device

The photoelectric switch is installed on the film carriage, automatic detect the height of the pallet

Driving motor: AC motor, speed adjustable

Power rated of film delivery driving motor: 0.37KW, SEW brand

Film delivery following up mechanism

The film delivery following up the rotary arm rotating, the proximity switch control the start/stop of film delivery motor to follow up the rotary arm

Film auto feeding and cutting device

When stretch wrapping finish, the film will be cut and clamped automatically.

When the film tail is released from the clamp, the air shooter will blow the film tail up, then the film tail will be wrapped by stretch film and keep it tightly with the pallet to ensure no film tail produced.

Film hot melt cutting adopts electrical heating wire to cut the film.

After film being cut, the hot sealer will seal the film tail automatically to ensure no film tail come out. Pneumatic component: FESTO brand

Pneumatic control system

Air source required: the compressed air shall be supplied by end user to the inlet of the stop valve.

The pneumatic cylinder is controlled by control box.

Control system

Photo-eye goods height sensor.

0-9 separate top, bottom & up-down wrap count selectors.

Photo-eye sensing delay.

Reinforce wrap allow more wrap on same location.

Film Tension Control adjustment on the panel.

3-15RPM arm variable a speed by frequency changer

Separate variable carriage up/down speed

Cycle pause capability.

Separate start, reset and emergency stop buttons.

Manual carriage up/down switch.

Turntable jog button.

Flash light for machine in operation.

Rotary arm stop by safety bumper and reflection photo eye sensing and obstacle in the rotating area.

Maintenance platform and ladder (option)

Main control System

PLC electric control system, touch screen panel.

Inverter control motor speed.

RELATED PRODUCTS